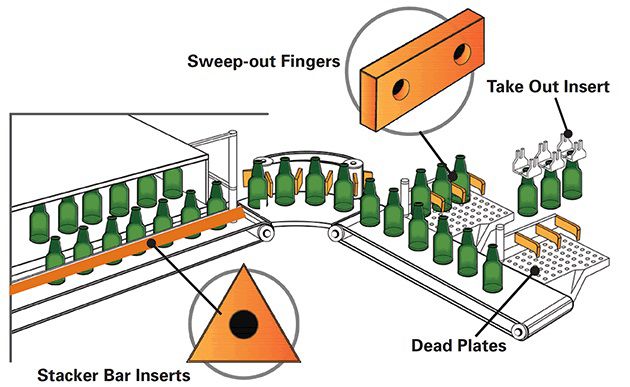

Glass Handling Sweep-Out Fingers

案例分析

VESPEL® SCP-5050 SWEEP-OUT FINGERS & STACKER BAR INSERTS

Veda-Pack, a leading Russian glass packaging company, needed to improve plant reliability. They had tested many different glass contacting materials with limited success, until they saw the results with Vespel® SCP-5050 sweep-out fingers and stacker bar inserts

The Challenge

To increase plant reliability, increase efficiencies and lower operating costs, glass bottle manufacturers continually search for materials that last long and will not damage the glass. Traditional carbon graphite components are extensively used in the industry but they present problems of breakage, short life, oil absorption and checking.

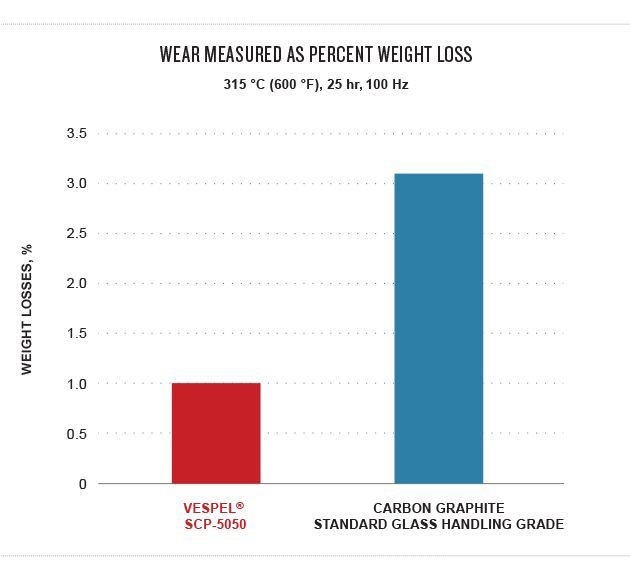

Wear Measure as Percent Weight Loss

The Solution

In an effort to improve plant reliability, Veda-Pack had continuously tested many different contact materials with limited success. Veda-Pack’s plant in St. Petersburg also tested Vespel® SCP-5050 sweep-out fingers and stacker bar inserts. Results were 2 to 3 times longer life than carbon graphite parts. Veda-Pack also reported that Vespel® SCP-5050 components do not absorb oil, resist breakage and are easy to machine. Plant mechanics and technicians commented they have never seen any hot glass handling materials perform better than Vespel® parts.

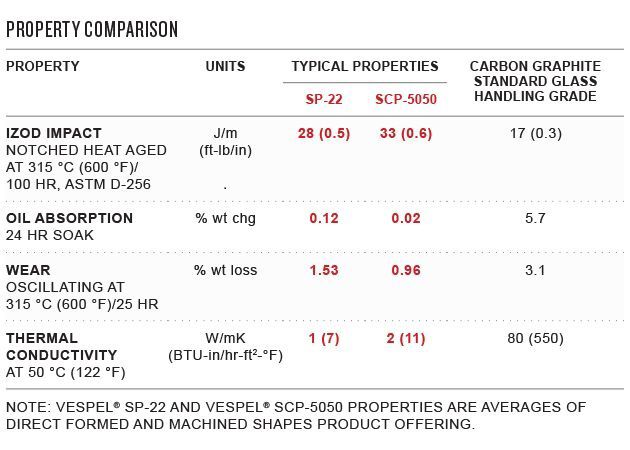

Property Comparison Chart

Key Advantages

DuPont™ Vespel® SCP-5050 parts are based on a proprietary polymer and represents a product innovation for the glass industry. Test results show 3 times less wear versus carbon graphite at 315°C (600°F) oscillatory conditions. Glass bottle plants have reported Vespel® SCP-5050 components to have a 2 to 11 times longer life over carbon graphite components. This translates into significantly higher life of consumables to increase production efficiency. In addition, Vespel® SCP-5050 components have a very low thermal conductivity, virtually no oil absorption and increased impact resistance which makes them ideal for sweep-out finger and stacker bar insert applications.