Vespel® ASB Channels Help Aircraft Thrust Reversers to Operate Longer and Safer

案例分析

Application

Thrust reversal is the temporary diversion of an engine’s exhaust so that it is directed forward rather than backwards. It helps slow down the aircraft just after touch-down, reducing wear on the brakes and enabling shorter landing distances. Translating cowl doors are opened and closed by moving sliders inside Vespel® ASB-0664 channels inserted into the nacelle’s beam. Smooth translation and low coefficient of friction is required, as well as low wear of the channels during the engine’s life.

Challenges

- Low friction below 0.20 to lower the actuation force.

- Ability to work between -70°C to 130°C (-22°F to 265°F).

- 40,000 to 80,000 operation cycles, depending on aircraft/engine type.

- High loading, 3 to 30 MPa (430 to 4300 psi), especially if required for a Rejected Take Off (RTO).

- Resistance to corrosion, aircraft fluids (oils, kerosene, cleaning agents), fungus, ice.

- Low weight.

Solution

- Vespel® ASB-0664 is an assembly of a resin impregnated fabric bonded to an aluminum substrate. Parts can withstand up to 232°C (450°F).

- Fabric provides low friction and durable coating to the aluminum channel while creating a corrosion barrier.

Features and Benefits

Wear resistance

Vespel® ASB-0664 has extensive use in nacelles and has proven itself over many years of service. Wear testing conducted over a variety of test conditions has demonstrated a part life of 80,000+ cycles, depending on specific application requirements.

Low friction

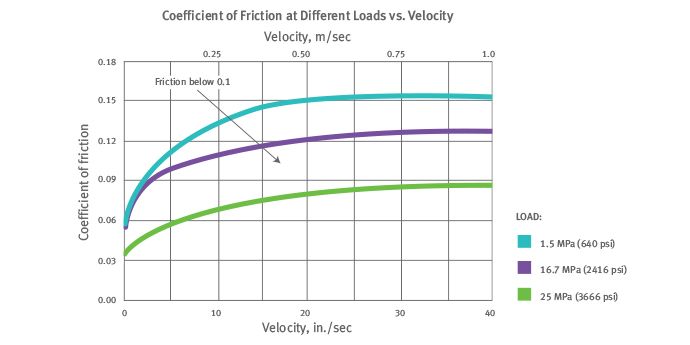

PTFE fibers enhance friction performance, dropping the dynamic coefficient of friction below 0.20. Higher loads only improve frictional behavior (Figure 1).

High strength

Parts can bear the typical high loading conditions of the landing as well as the severe conditions of potential Rejected Take-Offs (RTOs).

Corrosion and chemical resistance

The aluminum is heat treated to provide necessary hardness and stiffness. Anodizing protects the track liner from corrosion, while the fabric creates an insulating barrier between mating metal surfaces. Utilization of PTFE fibers provides parts that are resistant to most fluids used in aircraft operation and maintenance.

Light weight

The track liners in aluminum, like the sliders into the aluminum beams, allow weight savings for the nacelle.

Assembly and maintenance

The channel can be easily assembled into the aluminum beams. Customized attachment features can be added through additional machining or incorporation of attachment features. Channels can easily be removed and replaced if required.